AUTOMATIC DOYPACK PACKING MACHINE FOR LIOUID

- Support OEM/ODM Services

- Customized Packaging Machine Solutions

- Superior Quality, Competitive Pricing

- International Standard Packaging Equipment

- Trustworthy Global Partnerships

Leading Manufacturer of Packaging Machine

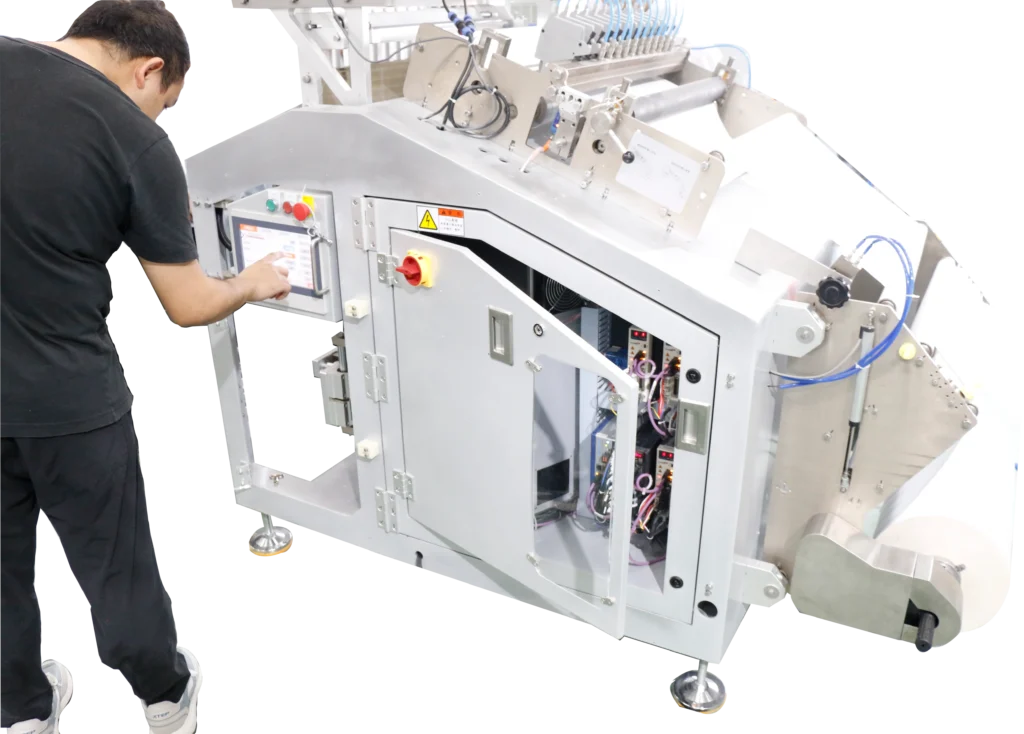

AUTOMATIC DOYPACK PACKING MACHINE FOR LIQUID

Suitable for diferent kinds of liquid products, Like juice, sauces, oil, liquid detergent, gel, medical liquid ect.

4 sides seal bag

Doypack bag

Zipper bag

Stand up pouch with spout

lrregular shape bag

CHARACTERISTIC AND ADVANTAGE

- Different machine models available to meet a wide range premade bag size.

- Customized main machine structure for various kinds of bag shape. Likedoypack zipper bag,4 side seal bag, stand up bag and irregular bag, ect.

- Multiple working station to meet full automatic process of bag pickup, dateprinting, bag opening, filling, bag arranging, sealing and output.

- With upgrade PLC control system, machine is easy for operation on touchscreen of parameter setting.

- Machine machine can equipment with different metering system like weigher,liquid pump, auger filler, bucket chain for different kinds of product filling andpacking in premade bag.

PRODUCT PARAMETERS

Model | ZE-160HPL | ZE-210HPL | ZE-260HPL | ZE-320HPL |

|---|---|---|---|---|

| Bag width | 80x160mm | 90x210mm | 150x260mm | 200x320mm |

| Bag length | 100x190mm | 110x330mm | 150x400mm | 150x500mm |

| Packing speed | 20-70bags/min | 20-60bags/min | 10-60bags/min | 10-50bags/min |

| Measuring range | 5~300ml | 50~1000ml | 200~2000ml | 500~3000ml |

| Power | 3kw50Hz | 3.5kw50Hz | 3.5kw50Hz | 3.5kw50Hz |

| Voltage | 220/380V | 220/380V | 220/380V | 220/380V |

| Air consumption | 0.5m³ | 0.5m³ | 0.7m³ | 0.7m³ |

| Weight | 600KG | 900KG | 1100KG | 1500KG |

| Size | (L)1400x(w)900x(H)1050mm | (L)2150x(W)1350x(H)1300mm | (L)2450x(W)1350x(H)1350mm | (L)2800x(W)1350x(H)1350mm |

20+ years of experience

Support OEM/ODM,we are a professional packaging machine factory.

- Cost-Effective Pricing

- Reliable Partnership

- Expert Solutions

- Superior Quality Assurance

- Comprehensive Service

- Delivered Globally

The most comprehensive range of packaging machines categories.

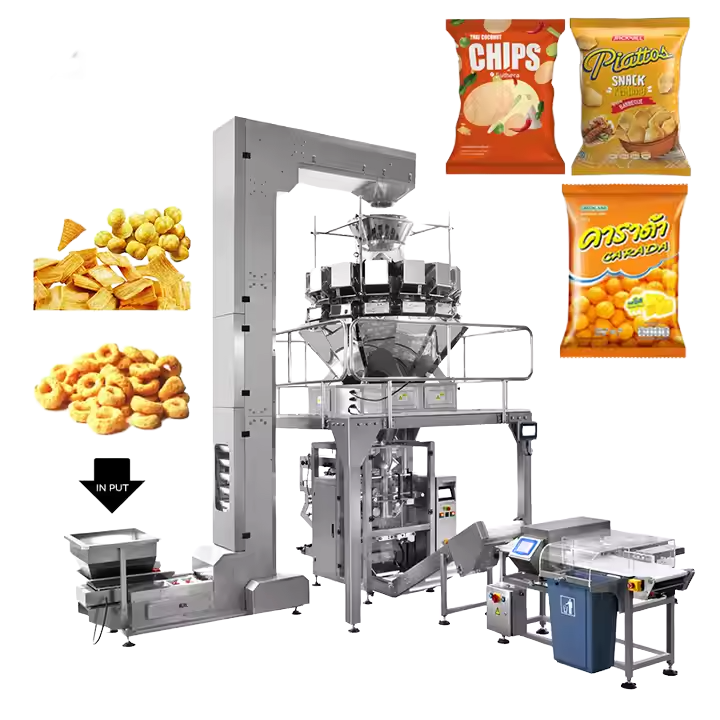

PACKAGING MACHINES BUILT FOR THESE INDUSTRY

CEREAL&NUTS

BICUITS&COOKIES

POWDER

PUFFED FOOD

STICK PACKAGE

SUGAR

VEGETABLE&FRUIT

SCREW

CANDY

LIQUID

MEDICAL

OIL

Trusted Packaging Machine Supplier

Customized Solutions

We understand that every business is unique, which is why we invest the effort to learn your specific requirement and customize our services. Our solutions aim to optimize your packaging process, reduce waste, and increase efficiency.

Ongoing Support

Our commitment to your success doesn’t end once the machinery is installed. We offer continuous maintenance and support, guaranteeing the optimization and efficiency of your packaging process.

Expert Advice

Our seasoned experts are always on hand to offer guidance and assistance. Whether you need help with a specific issue or want to explore new packaging options, we’re here to help.

Innovative Solutions

Our devoted team of experienced engineers and designers is focused on developing creative and adaptable packaging solutions that perfectly match our customers’ individual needs. We work closely with our clients to develop machines that are efficient, reliable, and cost-effective.

Quality Manufacturing

Our manufacturing facilities use only top-quality materials and advanced technology to produce our packaging machines. Our rigorous quality control measures ensure that every machine we produce meets or exceeds industry standards.

process of manufacturing Packaging Machine

1. Design

Designing the machine based on customer requirements and industry standards. This includes detailed drawings and specifications for every component.

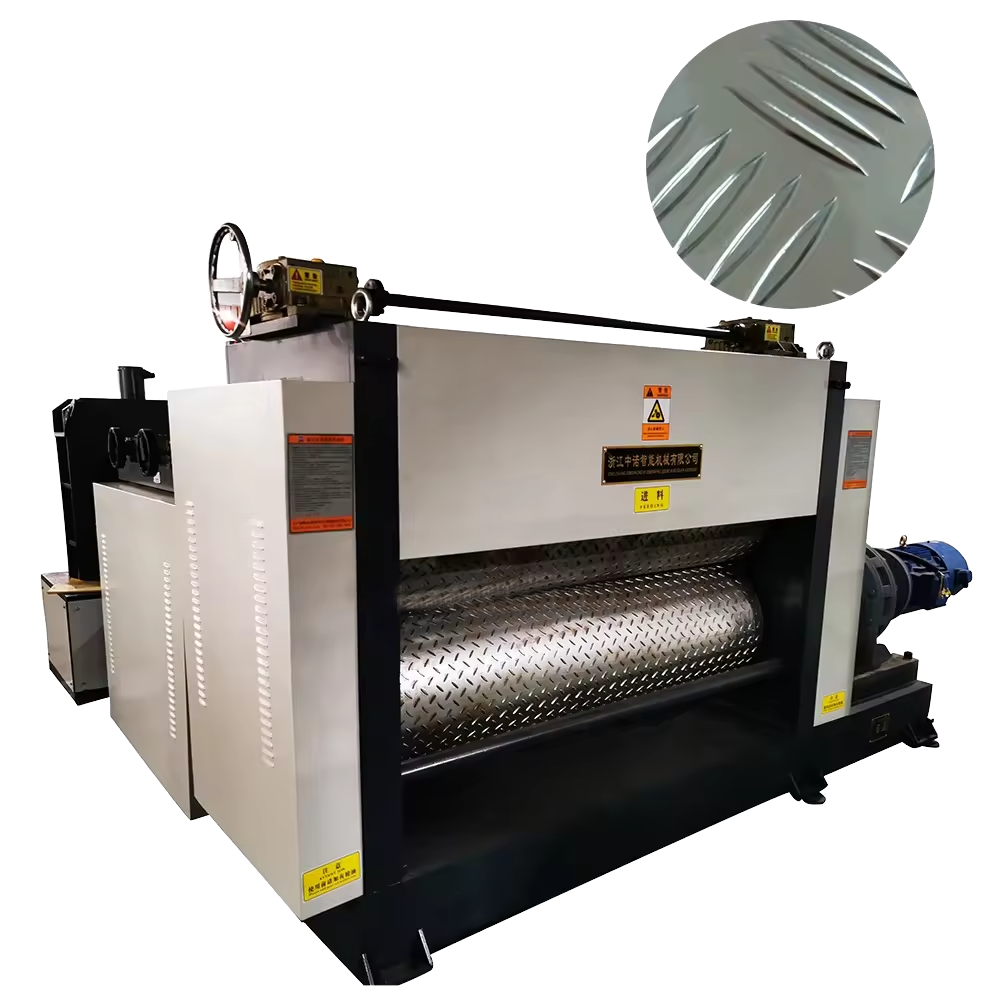

2. Fabrication

Once the design is complete, the machine’s parts are made using cutting, welding, and machining. This involves using high-quality materials such as stainless steel and aluminum.

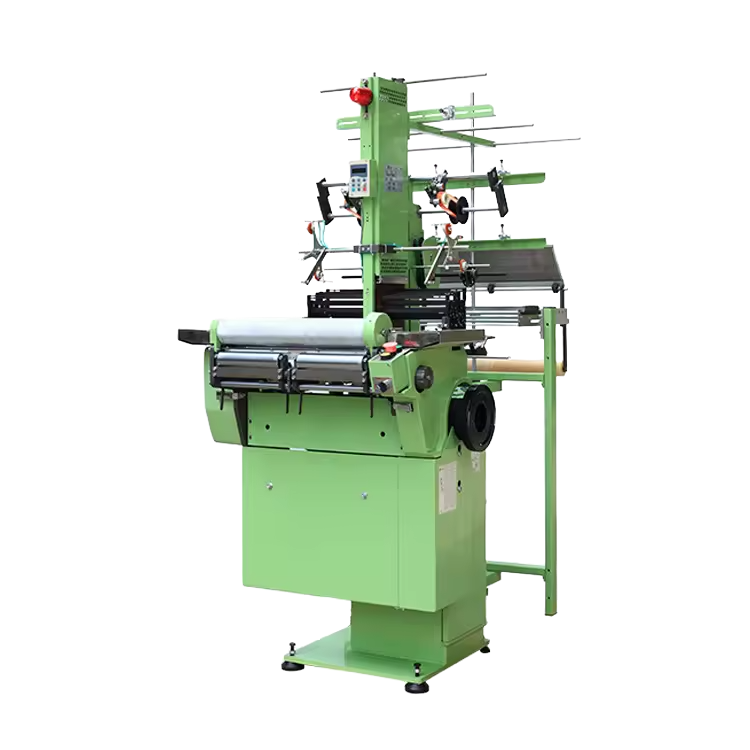

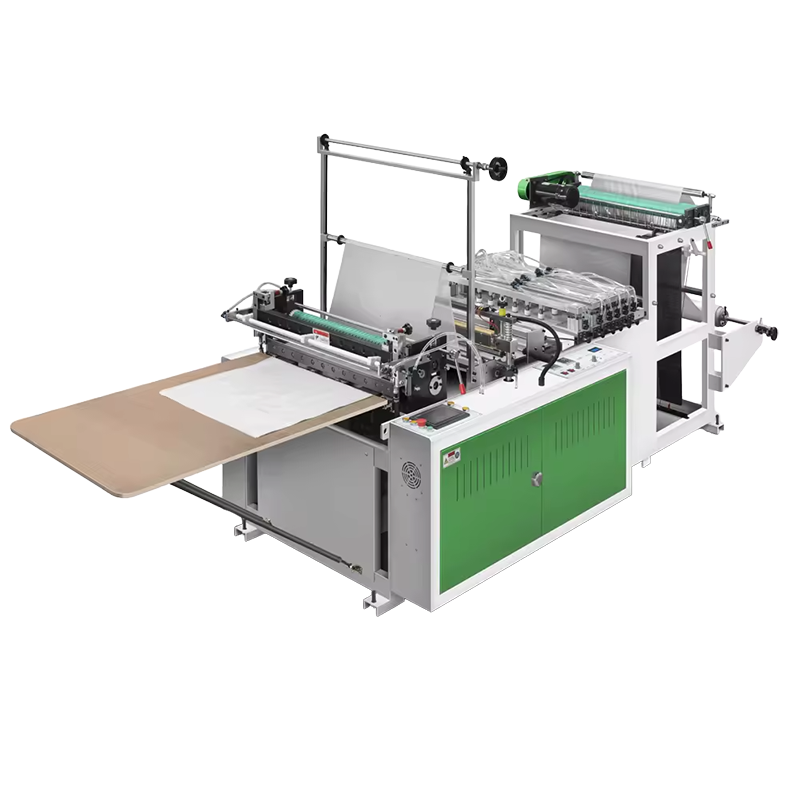

3. Assembly

The fabricated components are then assembled to create the complete vertical form fill seal machine. This includes installing the film roll holder, film forming section, filling station, sealing section, cutting section, and control system.

4. Testing

Once the machine is fully assembled, it is put through a rigorous testing process. Make sure it meets the specified performance criteria. Such as testing the machine’s speed, accuracy, and reliability under various operating conditions.

5. Installation

After the machine testing, it is installed at the customer’s facility. Configuring the machine to work with the customer’s specific packaging requirements. Training the customer’s operators on how to use the machine.

Start customizing your unique packaging machine today!